Motorcycle Parts New Zealand Specialists for Beginners

Wiki Article

Motorcycle Parts New Zealand Specialists Can Be Fun For Everyone

Table of ContentsMore About Motorcycle Parts New Zealand SpecialistsFascination About Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Fundamentals ExplainedIndicators on Motorcycle Parts New Zealand Specialists You Should KnowThe Definitive Guide for Motorcycle Parts New Zealand SpecialistsSome Known Details About Motorcycle Parts New Zealand Specialists 8 Easy Facts About Motorcycle Parts New Zealand Specialists ExplainedThe smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking About

Reach out to one of our specialists today.CNC machining technology is quickly becoming the prime focus of several manufacturing procedures around the globe as a direct result of its numerous advantages over other techniques. Furthermore, the sectors that make motorbikes have hopped on board with this fad. One of the most ingenious firms are currently establishing their engine elements and wheels making use of machining methods originally created for motorbike parts.

You might be asking yourself why we utilize. Now that we have your attention allow us describe the reasoning behind this contemporary advancement in the motorbike production sector.

About Motorcycle Parts New Zealand Specialists

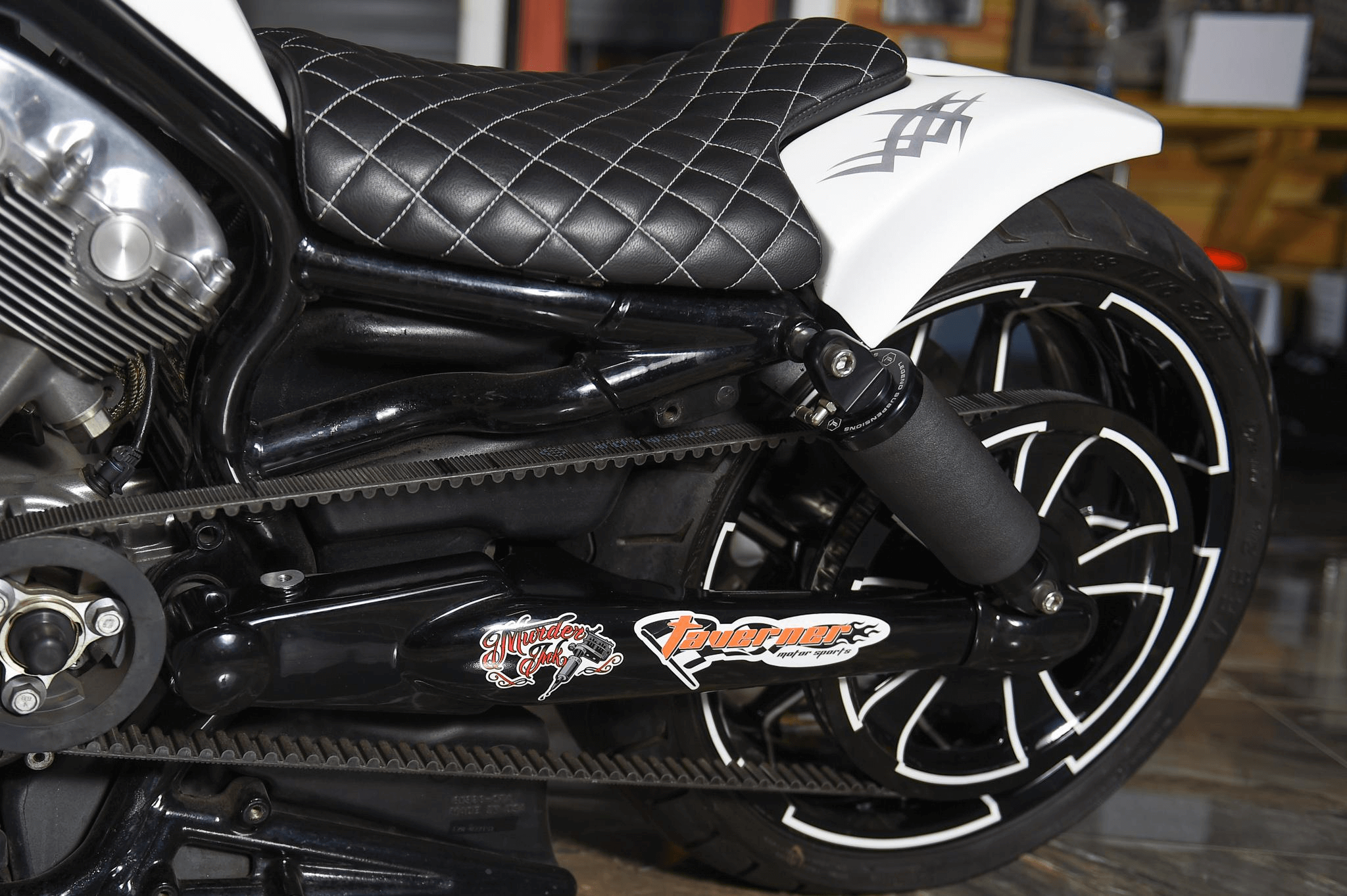

In enhancement, you have complete control over the appearance of the elements, even down to the min information. Sometimes, motorcyclists may make a decision to spruce up their adventure by installing aftermarket components or customizing the bike's remodeling.

Fascination About Motorcycle Parts New Zealand Specialists

CNC machining may be made use of to make virtually all of a bike's metal and plastic parts. To proceed, we'll go over numerous machined components for motorbikes.Milling procedures are made use of to obtain the preferred degree of wheel personalization. An additional aspect of the bike that might be individualized is the tires.

About Motorcycle Parts New Zealand Specialists

When it concerns a vehicle (or a motorcycle), the most important part is the engine. Several individuals point to it as the "heart" of the car. On the various other hand, the camshaft, the cylinder head, and the pistons have a tendency to be complex and need styles with a high level of precision.Usage only high-grade products, nonetheless, because these lights are vital for the safety and security of motorcyclists and other drivers or people on the road, particularly at evening. Bike fronts lights have 3 main components: the bulb, or light resource, the lens, and the housing.

Milling processes with a perfect surface would certainly lead to the lenses having a reflective quality that resembles that of a mirror. The cover, on the various other hand, is not composed of vulnerable materials; rather, it is constructed out content of hard polymers that can be machined into more detailed patterns.

Getting The Motorcycle Parts New Zealand Specialists To Work

They commonly have elaborate geometries with a wide range of min information. Motorbike makers typically cast these parts, but just for the production of bespoke components. CNC machining is the approach of selection when producing one-of-a-kind pieces. Machining on five axes in today's globe is the means through which any type of layout shape may be realized.Pick Runsom for your personalized motorcycle parts! We have the capability to make difficult and elegant parts making your bike matchless.

Right here are a couple of instances of metals commonly made use of in motorcycle part machining. Aluminum is the key material made use of by business specializing in creating customized bike elements to develop most of these parts - Motorcycle Parts New Zealand Specialists.

Zinc refers to one more steel that is really light in weight and has great machining high qualities due to its high mechanical strength. This product may be developed into virtually any kind of shape and keeps its measurements well. Also mission-critical parts that need a high degree of accuracy might gain from their use.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

An additional steel that sees heavy use in the manufacturing of CNC-customized components is magnesium. It is among the lightest steels that are currently see it here easily accessible and has exceptional machinability attributes and toughness proportionate with its reduced weight. Among the downsides of magnesium is that its dirt might conveniently ignite.

Due to its premium machinability and weldability, stainless-steel is an alloy that is specifically fit for CNC procedures. They have great rust resistance and a high aesthetic charm. Their most typical usage in generating various motorbike elements is bolts, such as screws and screws. Their reduced vulnerability to oxidation and deterioration makes them suitable for this usage.

Some Known Details About Motorcycle Parts New Zealand Specialists

It seems that CNC turning and grating are the foundational processes. In addition, it calls for maintaining bars of product, most frequently plastic or steel, in placement and then twisting a cutting tool to eliminate areas of the product as the product is turned.

These techniques are equally vital and produce components with high precision and regular quality. They are respectively: grinding, laser cutting, and exploration. The term "surface area finish" refers to post-processes after the preliminary machining stage. Motorcycle Parts New Zealand Specialists. The processes assist improve the general high quality of the machined bike parts. Below are the short introduction, advantages and disadvantages of five surface area treatment methods.

Not known Facts About Motorcycle Parts New Zealand Specialists

Report this wiki page